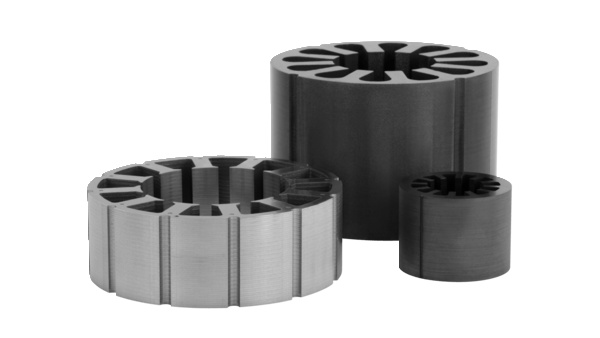

Lamination Stacks

Best-in-class Stator Packages and More

Lamination stacks are packages of individual sheets separated by electrically insulating layers to suppress eddy current losses under dynamic magnetic loading.

In-house manufactured cobalt-iron or nickel-iron strips in combination with adjusted production technologies are offering optimum stack solutions with respect to performance and costs.

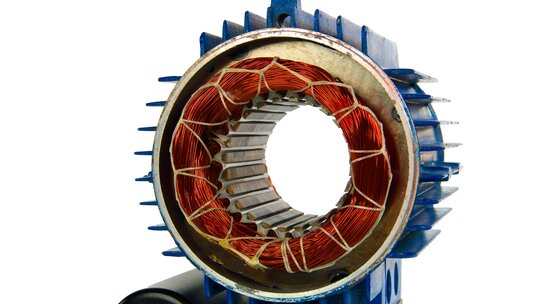

These parts are mainly used as stators and rotors in electric motors and generators but also as laminated cores.

Benefits:

- Best-in-class cobalt-iron and nickel-iron laminations down to 50 µm strip thickness

- Unique integrated production control from raw material to ready-to-use stacks including automotive and aerospace certification

-

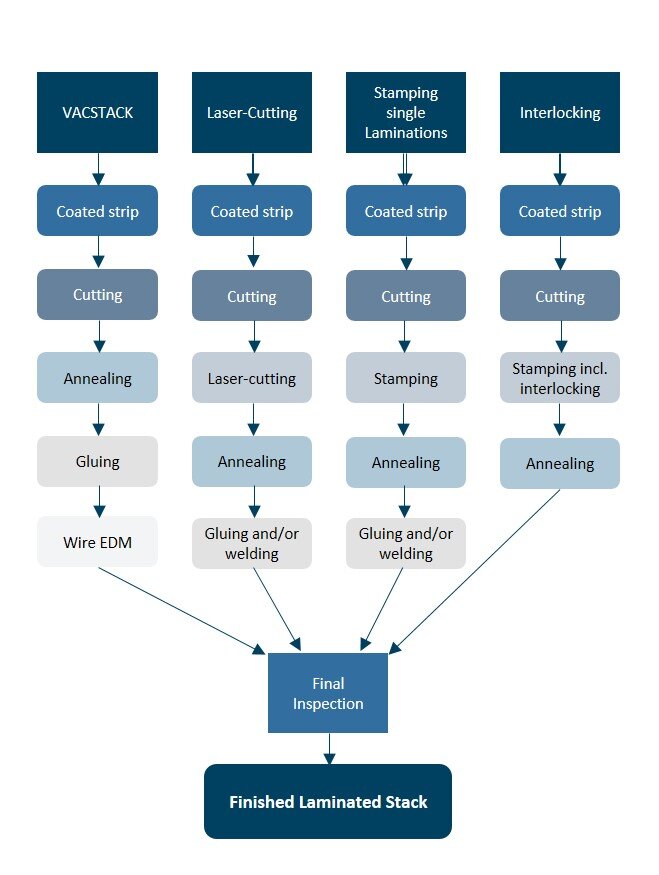

Huge variety of stacking technologies for prototypes as well as for mass production

-

Customized solutions to ensure highest performance and best value

- Stator and rotor stacks for electric motors and generators

- Laminated stacks for actuators, sensors or transformers

| Alloy | Alloy Group | Typical Thickness | max. Outer Diameter Stack (w/o segmentation) |

Available Stacking Technologies | |||

|---|---|---|---|---|---|---|---|

| t [mm] | ØO | VACSTACK (wire EDM) | Laser-cutting, gluing and/or welding | Stamping single laminations & gluing and/or welding | Interlocking | ||

| VACOFLUX® 48 | cobalt-iron | 0.055/0.1 | 220 | x | - | - | - |

| VACODUR® 49 | cobalt-iron | 0.1/0.2/0.35 | 320 | x | x | x | x(0.35 mm) |

| VACODUR® S plus | cobalt-iron | on request | 260 | x | x | x | x(0.35 mm) |

| VACOFLUX® X1 | cobalt-iron | 0.2 | 280 | x | x | x | |

| PERMENORM® 5000 V5 | nickel-iron | 0.2/0.35/0.5 | x | x | x | x(0.35 mm) | |

| MEGAPERM® 40L | nickel-iron | 0.1/0.2 | x | x | x | x(0.35 mm) | |

| ULTRAVAC® 44 V6 | nickel-iron | 0.1/0.2 | x | x | x | x(0.35 mm) | |

| MUMETALL® | nickel-iron | 0.2/0.35/0.5 | x | x | x | x(0.35 mm) |

Insulation Systems

- Cobalt-iron alloys: based on magnesium oxide (MgO)

- Nickel-iron alloys: based on zirconium oxide (ZrO) = HITCOAT, developed and patented by VAC

Gluing Technologies developed by VAC

- Standard adhesive K-01 for maximum package density

- High temperature adhesive HT-01 for applications up to 200 °C

- Stator and rotor stacks for electric motors and generators

- Laminated stacks for actuators, sensors or transformers

| Alloy | Alloy Group | Typical Thickness | max. Outer Diameter Stack (w/o segmentation) |

Available Stacking Technologies | |||

|---|---|---|---|---|---|---|---|

| t [mm] | ØO | VACSTACK (wire EDM) | Laser-cutting, gluing and/or welding | Stamping single laminations & gluing and/or welding | Interlocking | ||

| VACOFLUX® 48 | cobalt-iron | 0.055/0.1 | 220 | x | - | - | - |

| VACODUR® 49 | cobalt-iron | 0.1/0.2/0.35 | 320 | x | x | x | x(0.35 mm) |

| VACODUR® S plus | cobalt-iron | on request | 260 | x | x | x | x(0.35 mm) |

| VACOFLUX® X1 | cobalt-iron | 0.2 | 280 | x | x | x | |

| PERMENORM® 5000 V5 | nickel-iron | 0.2/0.35/0.5 | x | x | x | x(0.35 mm) | |

| MEGAPERM® 40L | nickel-iron | 0.1/0.2 | x | x | x | x(0.35 mm) | |

| ULTRAVAC® 44 V6 | nickel-iron | 0.1/0.2 | x | x | x | x(0.35 mm) | |

| MUMETALL® | nickel-iron | 0.2/0.35/0.5 | x | x | x | x(0.35 mm) |

Insulation Systems

- Cobalt-iron alloys: based on magnesium oxide (MgO)

- Nickel-iron alloys: based on zirconium oxide (ZrO) = HITCOAT, developed and patented by VAC

Gluing Technologies developed by VAC

- Standard adhesive K-01 for maximum package density

- High temperature adhesive HT-01 for applications up to 200 °C

Downloads

Related Products

VACOFLUX® X1

High performance combined with low weight is a key feature of motors built with this new low-cobalt-content alloy. Typically, motors can be realised that have a 20 to 30 % higher power density than with electrical steel.

49 % Cobalt-Iron

Thanks to their high magnetic saturation of up to 2.4 T, the cobalt-iron (CoFe) alloys VACOFLUX and VACODUR are generally suitable for all applications where high flux density and minimum weight are required. They are offering best possible parameters for highest performance electric motors/generators and magnetic actuators.

Components for Electric Motors

Whether you are looking for materials, permanent magnets or complete stator and rotor assemblies, we provide a comprehensive range of solutions for electric drives.

Contact Us Think Global - Act Local

We are looking forward to support you.